Composite rebar is a modern building material made of GFRP (Glass Fiber Reinforced Polymer), designed to substitute traditional steel reinforcement bars.This innovative material reinforces concrete with exceptional durability.Each composite reinforcement bar consists of a core rod with a spiral-wound belt around it, enhancing its strength and bonding capacity in concrete structures.

applications

Where is the composite rebar used?

• Ground Slabs (All types), RCC roads

• Concrete coverings, platforms, paths, parking lots, and roads

• Compound walls

• Swimming pools, reservoirs, conals

• Septic tanks, water tanks, ETP tanks

• Non-structural walls

• Secondary reinforcement (on selected structures)

• Pre-cast panels

• Walls made of fixed formwork, embankments, piers, slabs to strengthen the coastal strip

• Foundations of houses up to 3 floors (tape, base plates piles)

Illustrated

• Swimming pools

• Septic tanks

• Columns

• Bridges

• Roads

• Base slabs / industrial floors

• Foundations

• Walls

DuraFibar Advantages

DOUBLE LIFETIME compare with steel analogues – Fiberglass reinforcement DuraFibar has excellent chemicals properties which make them 100% anti-corrosive and alkaline resistant. This guarantees a long service life at least 80 years. The period of operation of a concrete structure with steel reinforcement is 2-3 times less than with a composite one in aggressive environment.

STRONGER on the disruption, than steel analogues – Fiberglass rebar DuraFibar is characterized by high tensile strength, parameters which are higher in 2-3 times than metal bars with the same diameter. DuraFibar guarantees a tensile strength of 1000 MPa (on selected diameter), which allows to replace steel products with a composite smaller diameter without loss of performance.

LIGHTER than steel analogues – The density of the components of fiberglass composite reinforcement does not exceed 1.9 tons per 1 cubic meter, which is at least 3-4 times less than the density of steel reinforcement. The reinforced concrete structure with similar strengths is 9 times heavier than the composite reinforcement structure.

CHEAPER than steel analogues – The price of fiberglass reinforcement often becomes the decisive factor when choosing between composite and metal products. When recalculating on metal rebars with the same strength characteristics, the saving can reach upto 40%

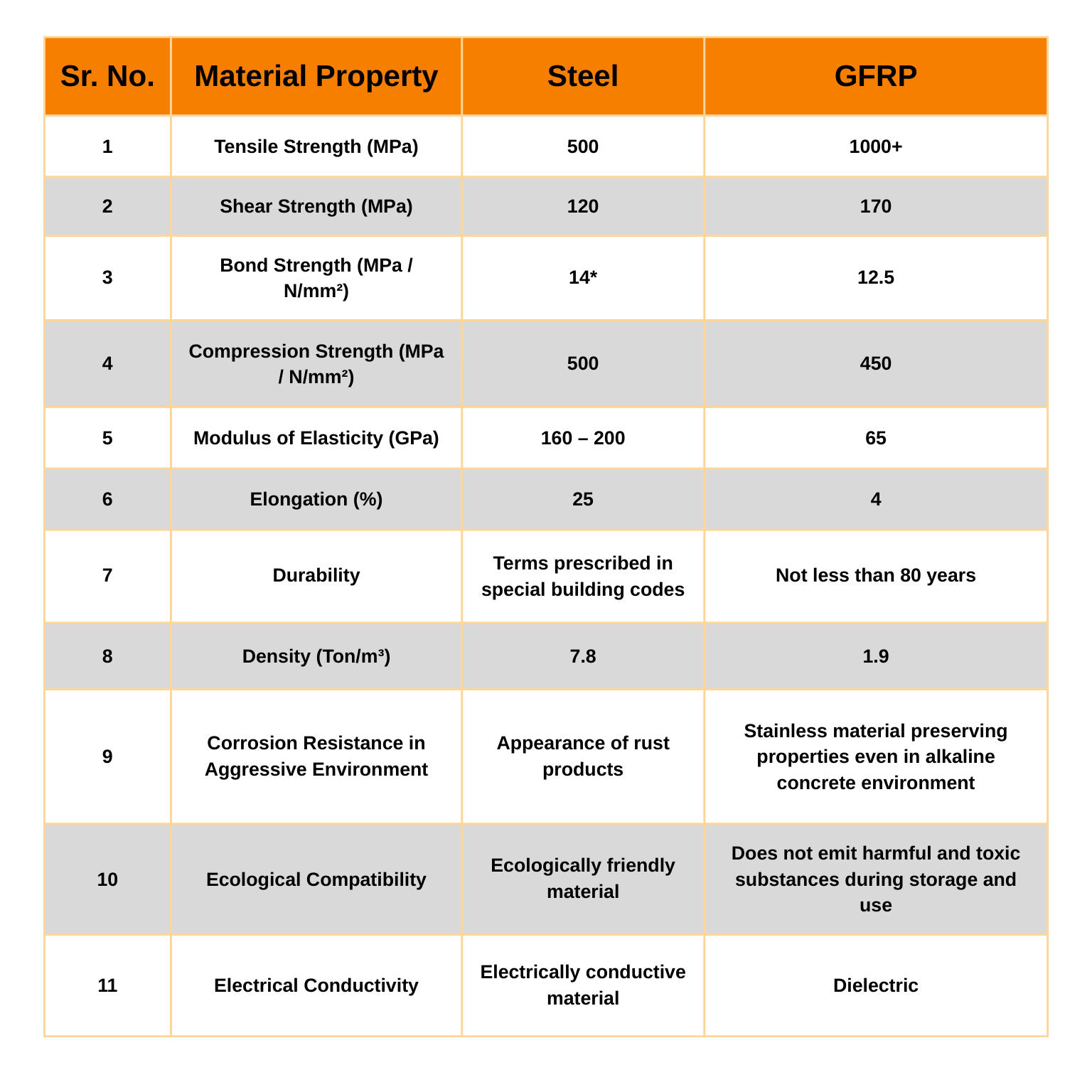

Steel vs GFRP : A Smarter Choice

Table of Substitution - by tensile strength

MetaL Rebar

9893161687 9352430687 9309418001

enquiry@vinayakaindia.co.in

Quick Links

Follow Us

© 2025 Vinent Enterprises. All rights reserved.